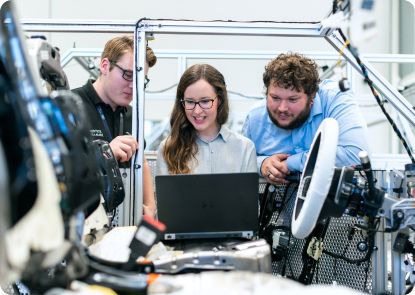

Helix IoT in Manufacturing

Predictive maintenance, supply chain optimization, quality control, real-time monitoring, smart factory concepts, energy efficiency, data-driven insights, worker safety, and operational efficiencies in manufacturing have all been improved by IoT innovations. These IoT-enabled enhancements boost productivity, enhance product quality, reduce costs, and drive continued innovation in the manufacturing industry.

World's Top Companies Rely on Our Trusted IoT Solutions

How does Helix connect manufacturers?

Helix provides customized connectivity solutions with expansive, scalable, and secure network coverage. Delivering reliable and secure connectivity enables real-time monitoring and control of manufacturing operations, optimizes processes, and enhances operational efficiency.

Schedule a meeting with an expert

Book A CallWhy Connect Manufacturing?

Benefits of IoT in Manufacturing

Not every SIM is a SmartSIM

SmartSIM

Connect any device, anywhere, with a single global SIM.

One Global Platform

Manage your entire IoT deployment through a unified SIM management platform.

One IoT Connectivity Partner

Seamlessly connect devices to local networks worldwide without managing multiple carrier relationships.

IoT Solutions in Manufacturing

How we benefit other industries

Ready to get started?

Fill out the form below to receive a free consultation and find out how Helix Wireless can help your business grow.